quick comparison

Quick comparison

General Comparison of COD with Conventional Ducting System

| Description of comparison | C.O.D. | Conventional Method | ||

|---|---|---|---|---|

| Outer Duct | Inner ducts | Outer Duct | Inner ducts | |

| Raw material | H.D.P.E | H.D.P.E | P.V.C. | H.D.P.E |

| Length | No limit | No limit | 6 meters(At maximum) | No limit |

| (Up to 500m or 1,000m) | ||||

| Connection | No need (saves materials and accessories) |

In every 6 m | ||

| Insertion of inner ducts | No need | To insert | ||

| Intermediate Manhole | No need to build | To build in turning point | ||

| Horizontal alignment of inner duct |

Straight | Straight | Straight | Straight |

| Saves optic cable about 3 to 5% | ||||

|

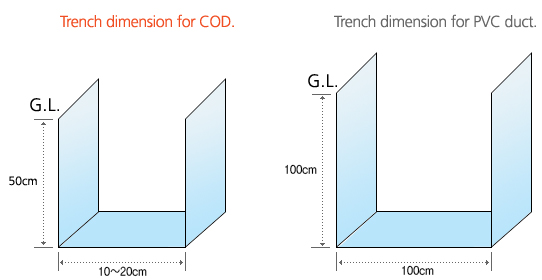

Trench Dimension (Volume) (28mm inner ducts in 112mm outer duct) (Dimension) |

(No need man-working space: vertical cut) Up to 5 inner ducts 0.3m(W) x 0.6m(H) |

(Slope cut to secure man-working space) 3 inner ducts only 0.5m(W) x 0.81m(H) |

||

| Trench Bedding | Rough bedding (passes over/by hurdles) |

Fine bedding | ||

comparison of work flow

Physical characteristics

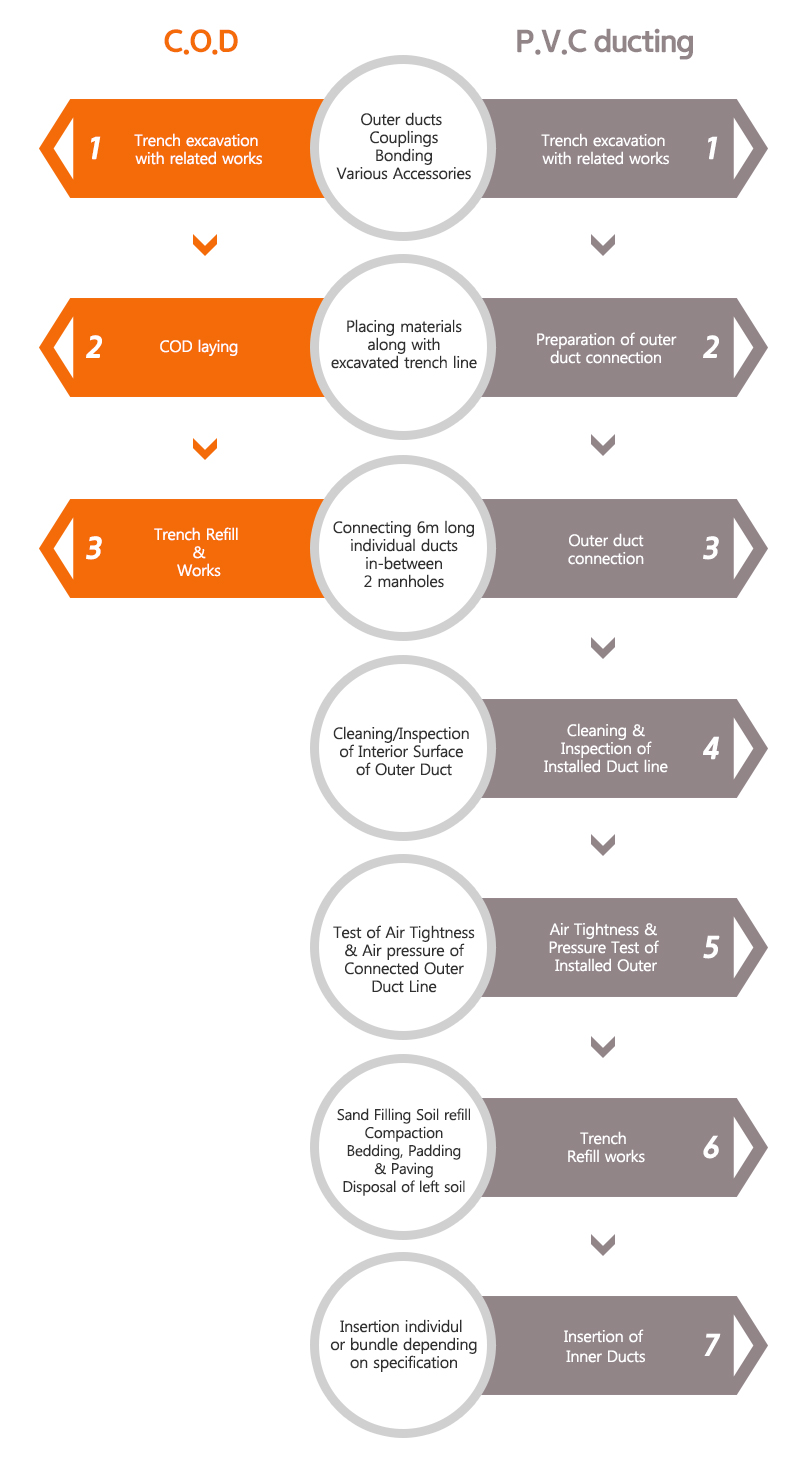

1. Work Flow

※ Note

1. PVC Ducting System needs 7 stages of working while COD only needs 3 working stages.

2. Above dimension is without consideration of man working space inside the excavated trench, but only vertical cut.

3. Above dimension does not show slope but vertical cut from bottom.

4. PVC ducting system needs 3 mobilizations:

1) Outer duct in the initial stage.

2) Cleaning, Inspection of installed Outer Duct Line and Inspection & Test of installed Outer Duct Line.

3) Inner duct for insertion.

1. PVC Ducting System needs 7 stages of working while COD only needs 3 working stages.

2. Above dimension is without consideration of man working space inside the excavated trench, but only vertical cut.

3. Above dimension does not show slope but vertical cut from bottom.

4. PVC ducting system needs 3 mobilizations:

1) Outer duct in the initial stage.

2) Cleaning, Inspection of installed Outer Duct Line and Inspection & Test of installed Outer Duct Line.

3) Inner duct for insertion.

physical characteristics

Physical characteristics

Physical characteristics of HDPE&PVC

| Physical Testing Items | Unit | HDPE | PVC | Remarks (HDPE) |

|---|---|---|---|---|

| Gravity | g/㎤ | 0.95 | 1.43 | Lighter |

| Tensile Strength | Kg/㎠ | 260~260 | 350~600 | More strength |

| Tensile Modulus | Kg/㎠ | 10,000~12,000 | 25,000~35,000 | Less Modulus |

| Curvature Strength | Kg/㎠ | 350 | 860~1,000 | Easier bending |

| Curvature Modulus | Kg/㎠ | 8,500 | 23,000 | Easier bending |

| Impact Strength | Kg.Cm/㎠ | <13.8 | 5~6 | More strong |

| Hardness | Shore-D | 64 | 70~90 | Less hard |

| Specific Heat | Kg.Cm/㎠ | 0.55 | 0.24 | More resistance |

| Softening Point | ℃ | 121 | 80~90 | More endurance |

| Limit of usage temperaure | ℃ | From -60~60 | From -5~60 | Much less limit |

| Withstand Voltage | Kv/mm, 1 minute | 48 | 28~32 | More reistance |

cost comparison

Cost comparison

Comparison of Economy of COD-5B vs PVC for

500 meters of COD 110mm(O.D.) with 90mm(I.D.) : 5 subducts of 28/33mm

500 meters of PVD 100mm(O.D.) with 90mm(I.D.) : 3 subducts of 28/33mm

US$1=\1,140Unit : US$

| Work Description | Calculation/ Job description |

Unit | Qty man/day |

Unit Cost |

Amount | Remarks |

|---|---|---|---|---|---|---|

| 1.Matrial: A. PVC Ducting System 1)Outer Duct 2)Inner Duct 3)Coupler |

PVC(100/90mm) HDPE tube(28/33) Or coupling material |

6m m Piece |

84 1,500 84 |

18.018 0.67 . |

1513.474 998.6842 0 |

. |

| Total | 2512.158 | |||||

| B. COD-5B . |

Outer Duct:90/110mm Inner Duct:28/33mm |

m . |

500 . |

6.14 . |

3070.175 . |

Readily built-in |

| 2. Installation A. PVC 1)PVC Laying 2)Connection of Outer Duct 3 Insertion of 5Inner Ducts 4)Cleaning of Outer Duct |

For 500m of PVC 145mm Duct & 5*42.4mm Inner Ducts. |

0.10M/D Per 6m 0.26M/D Per 6m 0.083M/D Per 6m 0.04M/D Per 6m 0.48M/D Per 100m 0.53M/D Per 100m 0.44M/D Per 100m (0.6+0.34) Per 100m |

||||

| Pipe Layer General Labor Pipe Layer General Labor Pipe Layer General Labor Pipe Layer General Labor |

(500m) (500m) (500m) (500m) (2,500m) (2,500m) (2,500m) (2,500m) |

8.40 21.84 0 0 0.02 0.02 0.00 0.00 |

||||

| Total | Pipe Layer General Labor Sub-total |

8.42 21.86 30.28 |

64.48 45.94 |

542.9997 1004.45 1547.447 |

Inner Duct(3+2):440% |

|

| Total Conventional System | 4059.605 | |||||

| Unit Cost of per linear meter of Inner Duct | 2.706 | US$/meter | ||||

| B. COD (for 5 Inner ducts: 2,500n) |

Pipe Layer General Labor |

(500m) (500m) |

28.50 9.00 |

64.48 45.94 |

1837.70 413.48 |

0.018M/D Per 100m 0.057M/D Per 100m |

| Sub-total | 37.50 | 2251.18 | Practically:50% applicable | |||

| Total COD | 5321.35 | |||||

| Unit Cost of per linear meter of Inner Duct | 2.129 | US$/meter | ||||

Comparison of Economy of COD-5B vs PVC for

500 meters of COD 110mm(O.D.) with 90mm(I.D.) : 5 subducts of 28/33mm

500 meters of PVD 145mm(O.D.) with 135mm(I.D.) : 5 subducts of 36.4/42.4mm

US$1=\1,140Unit : US$

| Work Description | Calculation/ Job description |

Unit | Qty man/day |

Unit Cost |

Amount | Remarks |

|---|---|---|---|---|---|---|

| 1.Matrial: A. PVC Ducting System 1)Outer Duct 2)Inner Duct 3)Coupler |

PVC(135/145mm) HDPE tube(35.4/42.4) Or coupling material |

6m m Piece |

84 2,500 84 |

58.772 0.921 . |

4936.842 2302.632 0 |

Estimate only |

| Total | 7239.474 | |||||

| B. COD-5B . |

Outer Duct:90/110mm Inner Duct:28/33mm |

m . |

500 . |

7.35 . |

3676.21 . |

Readily built-in |

| 2. Installation A. PVC 1)PVC Laying 2)Connection of Outer Duct 3 Insertion of 5Inner Ducts 4)Cleaning of Outer Duct |

For 500m of PVC 145mm Duct & 5*42.4mm Inner Ducts. |

0.12M/D Per 6m 0.32M/D Per 6m 0.083M/D Per 6m 0.04M/D Per 6m 0.48M/D Per 100m 0.53M/D Per 100m 0.44M/D Per 100m (0.6+0.34) Per 100m |

||||

| Pipe Layer General Labor Pipe Layer General Labor Pipe Layer General Labor Pipe Layer General Labor |

(500m) (500m) (500m) (500m) (2,500m) (2,500m) (2,500m) (2,500m) |

10.08 26.88 0 0 0.021 0.023 0.00 0.00 |

||||

| Total | Pipe Layer General Labor Sub-total |

10.10 26.90 37.00 |

64.48 45.94 |

651.3273 1236.00 1887.322 |

Inner Duct(3+2):440% |

|

| Total Conventional System | 9126.796 | |||||

| Unit Cost of per linear meter of Inner Duct | 3.651 | US$/meter | ||||

| B. COD (for 5 Inner ducts: 2,500n) |

Pipe Layer General Labor |

(500m) (500m) |

28.50 9.00 |

64.48 45.94 |

1837.70 413.48 |

0.018M/D Per 100m 0.057M/D Per 100m |

| Sub-total | 37.50 | 2251.18 | Practically:50% applicable | |||

| Total COD | 5927.39 | Material+Installation | ||||

| Unit Cost of per linear meter of Inner Duct | 2.371 | US$/meter | ||||

quick compariosn

Quick comparison

General Comparison of COD with Conventional Ducting System

| Description of comparison | C.O.D. | Conventional Method | ||

|---|---|---|---|---|

| Outer Duct | Inner ducts | Outer Duct | Inner ducts | |

| Raw material | H.D.P.E | H.D.P.E | P.V.C. | H.D.P.E |

| Length | No limit | No limit | 6 meters(At maximum) | No limit |

| (Up to 500m or 1,000m) | ||||

| Connection | No need (saves materials and accessories) |

In every 6 m | ||

| Insertion of inner ducts | No need | To insert | ||

| Intermediate Manhole | No need to build | To build in turning point | ||

| Horizontal alignment of inner duct |

Straight | Straight | Straight | Straight |

| Saves optic cable about 3 to 5% | ||||

|

Trench Dimension (Volume) (28mm inner ducts in 112mm outer duct) (Dimension) |

(No need man-working space: vertical cut) Up to 5 inner ducts 0.3m(W) x 0.6m(H) |

(Slope cut to secure man-working space) 3 inner ducts only 0.5m(W) x 0.81m(H) |

||

| Trench Bedding | Rough bedding (passes over/by hurdles) |

Fine bedding | ||

general comparison

General Comparison

General Comparison Table of COD to Conventional Duct

| Category | Conventional P.V.C. Duct | C.O.D. (Corrugated Optic Duct) |

|---|---|---|

| Material & Strength |

- PVC: vulnerable to impaction damage - Disconnection: Possibility of dis-connection of connected points of outer duct due to ground compressive load. - Thermal expansion & contraction during the installation period and in service |

- Stand good against impaction damage and no damage risk from freezing temperature. - Strong Concavo-convex shape provides good strength and stays same shape against ground compressive load. - Stays stable from thermal expansion & contraction of duct during or after installation |

| Installation |

- Many individual connections: maximum length is 6 meters. - To construct manhole to diverse direction of the line. - Complicated installation work as the insertion of inner ducts is in the second stage after the installation of outer duct. - Causes traffic troubles (jamming) in case of urban installation. - Inner duct may twist in the course of insertion. - Maximum number of inner duct is limited to 3 ducts. |

- No duct connections in-between two manholes up to 500 meters or more. - Single installation process: No need to go through complicated inner duct insertion process owing to readily built-in both outer and inner ducts. - To by-pass minor hurdles and skips un-necessary construction of manhole to diverse direction of line within the radiation of curbing angle. - Increase of duct efficiency by increase of numbers of inner ducts to be inserted up to 5 ducts at approx. same price. - Light weight allows easy handling and transportation. |

| Economy | - High construction cost. | - Economic construction cost and time saving |